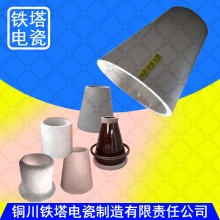

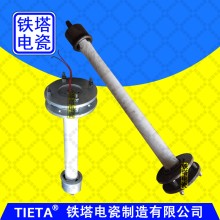

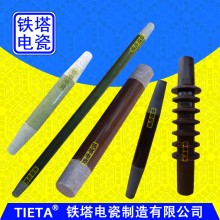

静电除尘器瓷柱用于静电除尘器支撑悬挂电晕极悬挂框架,起支撑和高压绝缘作用,瓷柱绝缘子适用于工作温度不超过250℃、直流工作电压72KV~120KV,安装地点海拔高度不超过1000米的工作条件下使用。

瓷柱绝缘子严格按照GB/T772-2005《高压绝缘子瓷件技术条件》和JB/T6746.3-93《电除尘器用瓷绝缘子》制造。绝缘子由瓷件和上下金属附近用耐高温胶合剂胶装而成,瓷件端面与金属附近胶装接触部分垫有耐高温弹性衬垫,瓷件胶装部位采用滚花,上砂等结构,防止松动,扭转,以保证机械强度。瓷件表面施白色或棕色瓷釉,金属表面涂高温油漆。

注:不同瓷质等级的瓷件耐温≤250℃、≤350℃、≤500℃、环境中使用,工作电压为72-120KV,抗压破坏负荷不低于300KN。

使用各种瓷瓶绝缘子产品时必须安装平整受力均匀,运行设备前先给瓷瓶及安装位置加热烘干12-24小时左右(保证瓷瓶及安装位置清洁干燥,不能有油污等潮湿现象,检查电压是否符合要求)才能运行设备),突然升温降温会导致温差引起瓷瓶炸裂。

Electrostatic precipitator porcelain columns are used for electrostatic precipitator support and suspension of corona electrode suspension frames, serving as support and high-voltage insulation. Porcelain column insulators are suitable for use under operating conditions where the operating temperature does not exceed 250 ℃, the DC operating voltage is 72KV to 120KV, and the installation site is located at an altitude of not more than 1000m.

Porcelain post insulators are manufactured in strict accordance with GB/T772-2005 "Technical Conditions for High Voltage Insulators and Porcelain Insulators for Electrostatic Precipitators" (JB/T6746.3-93). Insulators are made of porcelain pieces and the vicinity of the upper and lower metal using high-temperature resistant adhesive. The contact part between the end face of the porcelain piece and the vicinity of the metal is padded with high-temperature resistant elastic pads. The bonding part of the porcelain piece adopts knurled, sanded, and other structures to prevent loosening and twisting to ensure mechanical strength. The surface of porcelain parts shall be painted with white or brown enamel, and the metal surface shall be painted with high-temperature paint.

Note: Porcelain parts of different porcelain grades have a temperature resistance of ≤ 250 ℃, ≤ 350 ℃, ≤ 500 ℃, and are used in the environment. The working voltage is 72-120KV, and the compressive damage load is not less than 300KN.

When using various porcelain insulator products, it is necessary to install them smoothly and evenly under uniform stress. Before operating the equipment, heat and dry the porcelain bottle and installation location for about 12-24 hours (ensure that the porcelain bottle and installation location are clean and dry, free of moisture such as oil stains, and check whether the voltage meets the requirements) before operating the equipment. Sudden temperature rise and drop can cause the porcelain bottle to explode due to temperature differences.